Knowledge of equipment and machinery, how it works and what it does, is very important for a solid understanding and application of the Lockout Tagout (LOTO) policy. Every site should have equipment specific LOTO procedures, and only authorized employees that have had hands on training on a specific piece of equipment should be involved with the Lockout and Tagout process.

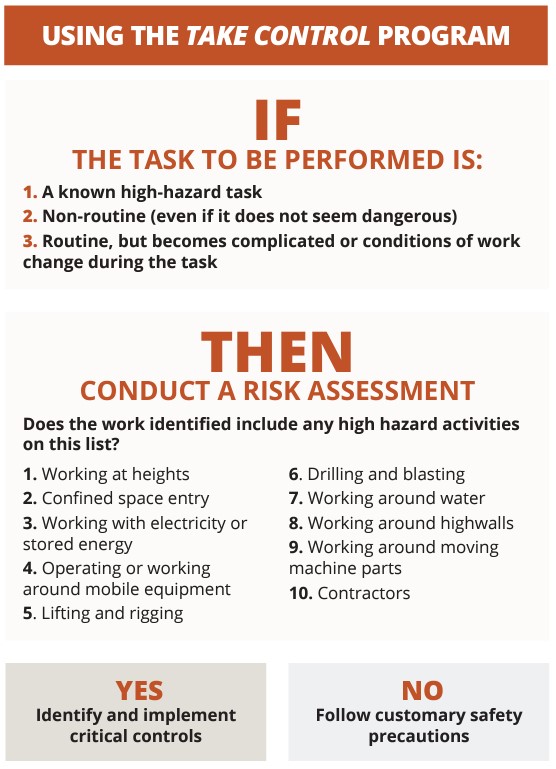

HIGH-RISK TASKS: The following are examples of types of energy with a high SIF potential. This list is not exhaustive and critical controls should be implemented for all work requiring lockout/tagout or when working with stored energy.

– Electrical energy: Maintenance on any equipment that is powered by electricity, batteries, or internal combustion engines

– Stored energy: Maintenance of hydraulic and pneumatic equipment/implements (e.g., hydraulic arms)

– Potential energy: Maintenance of something with the potential to move, shift, or rotate (e.g., equipment that has an eccentric shaft or is in an unstable position when not operating)

– Gravitational energy: Work with a gravitational component (e.g., materials with potential for engulfment)

CRITICAL CONTROLS

– Electrical energy sources are properly identified and locked and tagged out.

– Equipment adjacent to, directly above or below and equipment feeding or discharging from the equipment to be worked on is locked and tagged out.

– Equipment is tested to demonstrate that the proper equipment is locked out and re-energization cannot occur. Independent verification (i.e., verification by a supervisor or competent person) is preferred; if independent verification is unavailable, then a self-check is performed.

– Company arc flash procedures are in place, understood and followed.

– Stored pressure is bled off, drained, blanketed and/or isolated for lines carrying pressurized material.

– Prior to performing maintenance on a piece of stationary or mobile equipment, all components are secured from movement or activation and a check for zero energy is conducted.